Read Online Electrical discharge machining and laser beam processing: Adaptive pulse width modulation on locally positioned targets - Yoshishge Ohyama | PDF

Related searches:

Electrical Discharge Machining Wire EDM Header Die & Tool Inc.

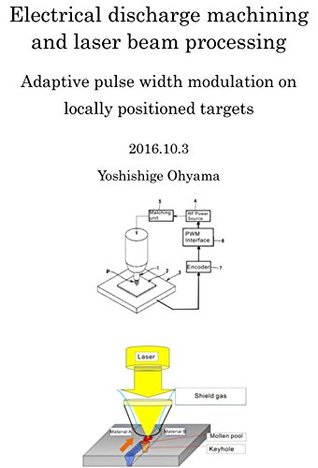

Electrical discharge machining and laser beam processing: Adaptive pulse width modulation on locally positioned targets

Electrical Discharge Machining 101 Resources Fast Radius

In-House Electrical Discharge Machining Wire, Sinking, Hole

Electrical Discharge Machining - an overview ScienceDirect

How Does Electrical Discharge Machining Work?

Electrical Discharge Machining (EDM): Parts, Working

Electric Discharge Machining: Advantages and Disadvantages

All About EDM Machining (Electrical Discharge Machining)

MACHINING CHARACTERISTICS OF ELECTRICAL DISCHARGE MACHINING

Why Electrical Discharge Machining are Popular over Other

Electrical Discharge Machining (EDM) Hermetic Solutions Group

Electrical Discharge Machining • MicroGroup

Electrical Discharge Machining (EDM) in Contract Manufacturing

Shop Electrical Discharge Machining - mscdirect.com

Everything You Should Know About Electrical Discharge Machining

Electrical Discharge Machining (EDM) - Mercer University

Electrical Discharge Machining (EDM) AERO Manufacturing

(PDF) Electrical Discharge Machining (EDM): A Review

Electrical Discharge Machining (EDM) Temco Tool Inc.

EDM (Electrical discharge machining) - Wire edm die sinker edm

Electrical Discharge Machining: Definition, Working, Parts

Modeling of the Anode Crater Formation in Electrical Discharge

EDM (Electrical Discharge Machines) - Kent Industrial USA

Electric Discharge Machining: Parts, Working, Applications

machining - Huge selection. Good Prices.

A machining method typically used for hard metals, electrical discharge machining (commonly known as edm machining) makes it possible to work with metals for which traditional machining techniques are ineffective. An important point to remember with edm machining is that it will only work with materials that are electrically conductive.

Get expert solutions from our highly experienced machine tool team with a combined 155+ years of experience.

May 17, 2018 edm is a subtractive manufacturing method that uses electrical discharges to machine features on a mold.

Electrical discharge machining is also called or known as spark machining, spark eroding, burning, die sinking, wire burning or wire erosion. This is a manufacturing operation in which we used to make desired shapes by using an electrical spark.

Electro discharge machining (edm) process is a non-conventional and non-contact machining operation which is used in industry for high precision products.

At aero manufacturing we use a process known as sinker electrical discharge machining. First discovered in the early 1940s, this method is frequently used in tool and die applications to create intricate shapes and challenging parts. Edm processes present several advantages for custom metal fabrication.

Electrical discharge machining definition: it is a process in which electrical energy is used to generate the spark between the tool and workpiece submerged under the dielectric medium so that material removal takes place from the surface of the workpiece by local melting or vaporization called as electric discharge machining.

Electrical discharge machining, or edm, is a non-traditional method in which material is removed from a workpiece using thermal energy. Much like processes such as laser cutting, edm does not need mechanical force in the removal process.

What is electrical discharge machining -definition electrical discharge machining (edm), which is also known as spark machining, spark dissolving, kick the bucket sinking, wire copying, or wire disintegration, is an assembling procedure whereby an ideal shape is acquired by utilizing electrical discharges (sparks).

Electrical discharge machining is an advanced machining technique that allows for precise, detailed cuts that were once thought to be out of reach with traditional.

Sinker edm, wire edm and hole drilling edm are products manufactured by gf machining solutions.

Electrical discharge machining a more precise, non-contact method to cut conductive materials titanium, stainless steels, aluminum and heat-treated tool steels can be cut with efficiency. Tapered shapes, complex forms and unique parts can be machined burr-free and with extremely high precision.

May 26, 2020 electrical discharge machining (edm) is a non-traditional machining process. The material is removed from a workpiece, without any mechanical.

Edm generalities •electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with traditional techniques. •edm typically works with materials that are electrically conductive, although methods have also been proposed for using edm to machine insulating ceramics.

A number of processes fall under the umbrella of cnc machining, including turning, milling, cutting, engraving, and electrical discharge machining (edm).

Electrical discharge machining, also known as spark machining or arc machining, is a unique manufacturing process whereby material is removed from a workpiece by a series of recurring electrical discharges.

Electrical discharge machining (edm) is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges between tools, called electrodes, and the part being machined in the presence of a dielectric fluid.

Jan 11, 2018 electrical discharge machining (edm), the application of the electrical discharges under a controlled mechanism to remove metal, has long.

Jun 25, 2019 electrical discharge machining (edm) is the ticket. It's also known as arc machining, spark machining and burning, and the superb surface finish,.

Electrical discharge machining is the machining of a material through the direction of high-frequency electrical spark discharges from a tool, usually made of graphite.

The anode crater formation during electrical discharge is composed of two phases: plasma heating and bubble collapsing.

In our wire electrical discharge machining (wedm), also known as wire-cut edm and wire cutting process, a thin brass wire, is fed through the workpiece,.

What is electrical discharge machining? also known as spark machining, wire erosion, die sinking and spark eroding, edm is a manufacturing process.

This type of machining process, sometimes referred to as spark machining, die sinking or burning, is when an electrical discharge is used to shape materials.

Electrical discharge machining (edm), also known as “spark” machining, is a technology that has been in existence for a long time. During the edm process, an electrical current is directed to pass between an electrode and a workpiece that has been separated by a dielectric liquid, which acts as an electrical insulator.

Electric discharge machining, also known as spark erosion, electro-erosion or spark machining is a process of metal removal based on the principle of erosion of metals by an interrupted electric spark discharge between the electrode tool cathode and the work anode.

Electrical discharge machining frequently used in tooling and molding processes for a broad expanse of industries, such as aviation, aerospace and gas turbines, electric discharge machining (edm) uses thermal energy to remove excess material from an object to create the shape needed for a certain task.

Nov 2, 2019 electrical discharge machining is the machining of a material through the direction of high-frequency electrical spark discharges from a tool,.

Post Your Comments: